Address:China

Working time :Monday to Friday: 7am to 7pm

Weekends: 10am to 5pm

Address:China

Working time :Monday to Friday: 7am to 7pm

Weekends: 10am to 5pm

The reason why pasteurized egg liquid can be recognized by customers is inseparable from these advantages of the product itself.

Nutrition and health: Pasteurized egg yolk liquid selects high-quality fresh eggs as raw materials. The pasteurization process is used in the egg production process to retain the nutrition of the eggs themselves while ensuring the safety of the egg liquid.

Strong stability: The quality management standards in the egg production process of pasteurized egg liquid are strict, and each batch of egg liquid is inspected after completion to ensure the stable quality of the egg liquid. In addition, pasteurized egg yolk liquid is refrigerated at low temperatures throughout the entire storage and transportation process, maintaining the stable quality and taste of the egg liquid.

Convenient and easy to use: Pasteurized egg yolk liquid is designed in bag packaging and can be used immediately after opening the bag. It can be directly used in food processing or cooking, greatly shortening the meal preparation process and improving the production efficiency of food enterprises.

High cost performance: The price of pasteurized egg yolk liquid is stable, and there is no need to manually beat and separate eggs when used, saving labor costs and time costs, and is more suitable for large-volume purchases by food processing companies.

Liquid eggs are not only safe, they are ready to use, saving time in preparing egg liquid.

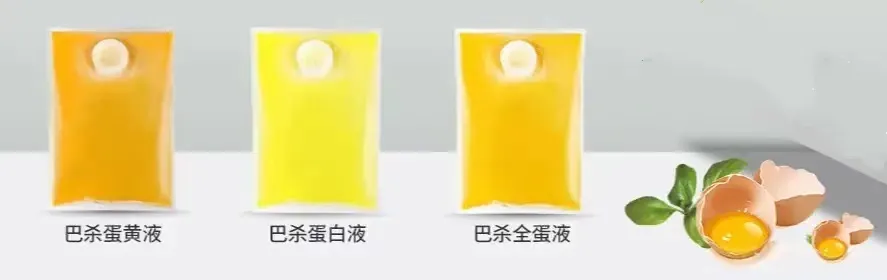

Under normal circumstances, food and catering companies consume a large amount of eggs every day. If shell eggs are used, a lot of time and energy will be spent on pre-made egg liquid, which will increase the cost. Using egg liquid can solve this problem well. . Fresh eggs are used as raw materials, and after egg cleaning, egg breaking, egg separation, homogenization, sterilization, cooling and other egg processes, fresh egg liquid is made, which further reduces the cost of egg liquid pre-processing and can be used immediately after opening the bag, which improves work efficiency. . Fresh egg liquid is divided into many types such as egg white liquid, egg yolk liquid, whole egg liquid, and egg tart liquid. You can choose according to your needs. It is very convenient whether you are cooking dishes or baking pastries.

Reduce losses and save waste processing time

During the long-distance transportation of fresh shell eggs, collisions will inevitably occur, causing some eggs to be damaged. There is a certain degree of uncertainty in manual operations. There may also be certain losses during the egg liquid pre-production process, and these losses often need to be borne by the user. In addition, shell eggs need to be fully cleaned before use, and the egg liquid holding containers also need to be cleaned regularly, which requires a large amount of water resources. Processing eggshells takes time and effort, and also increases the operating costs of the company. You don’t have to worry about these when using fresh egg liquid. Fresh egg liquid is packaged in bags, which has a low probability of loss during transportation. It can be used directly after opening the bag without generating too much waste. The outer packaging is easy to handle, and liquid eggs will not The production of eggshell and other garbage residues allows food processing manufacturers to better ensure workshop hygiene. It can help enterprises reduce costs and increase efficiency.

As the national food health awareness increases, egg liquid gradually replaces fresh eggs and becomes a common ingredient for food companies and chain restaurants. The quality of ingredients affects food safety. Choosing a reliable egg liquid manufacturer is crucial to food production and quality. So, how can we choose a reliable egg liquid processing manufacturer? I would like to remind everyone to focus on these issues.

The most critical issue in food procurement is safety, so it is crucial to choose a manufacturer with relevant qualification certificates. Regular egg liquid manufacturers should have production licenses, health licenses and quality management system verification. When choosing a manufacturer, be sure to verify whether it has the necessary qualification certificates and pay attention to the validity and authenticity of the certificates to ensure the quality of the egg liquids. Hygiene and quality meet national standards.

According to different compositions, egg liquid can be divided into whole egg liquid, egg white liquid, and egg yolk liquid. Egg yolk liquid is often used in making sauces and ice cream, egg white liquid is often used in bread and cake baking, and whole egg liquid is often used in fried meat and dish cooking. . The production of different foods requires different types of egg liquid. Therefore, when choosing an egg liquid processing manufacturer, you should pay attention to whether its product range is rich and whether it can meet your own needs.

In addition, you also need to pay attention to the manufacturer’s supply capacity. Larger and more automated egg liquid factories usually have stronger supply capabilities, which can ensure timely supply of products and avoid affecting food production due to shortages or out-of-stocks.

Egg liquid requires cold chain logistics storage and transportation, so it is also very important to choose a manufacturer with strong cold storage area and transportation and distribution capabilities. Manufacturers with strong storage and transportation capabilities can ensure the quality and safety of egg liquid during transportation.

To sum up, a reliable egg liquid processing plant is indispensable in terms of qualifications, product categories, supply strength, and storage and transportation capabilities. Food companies and chain restaurants must keep their eyes peeled when choosing, and make a decision after comprehensive comparison.

If you still don’t know how to choose an egg liquid manufacturer, you might as well contact Taixing Aerospace Machinery Technology Co., Ltd to try it out. Taixing Aerospace Machinery Technology Co., Ltd, with complete qualifications and certifications, a complete management system, a modern production base and rich experience in the research and development and production of egg processing machinery, has long provided the market with egg breaking machines, egg shelling machines, and quail egg peeling machines. , egg washing machines, egg liquid processing equipment and other diversified egg machinery, with strong supply strength and guaranteed product quality! Taixing Aerospace Machinery Technology Co., Ltd will introduce you to high-quality egg liquid manufacturers.