Адрес:Китай

Время работы: понедельник - пятница: с 7 утра до 7 вечера

Выходные: 10 утра до 5 вечера

Адрес:Китай

Время работы: понедельник - пятница: с 7 утра до 7 вечера

Выходные: 10 утра до 5 вечера

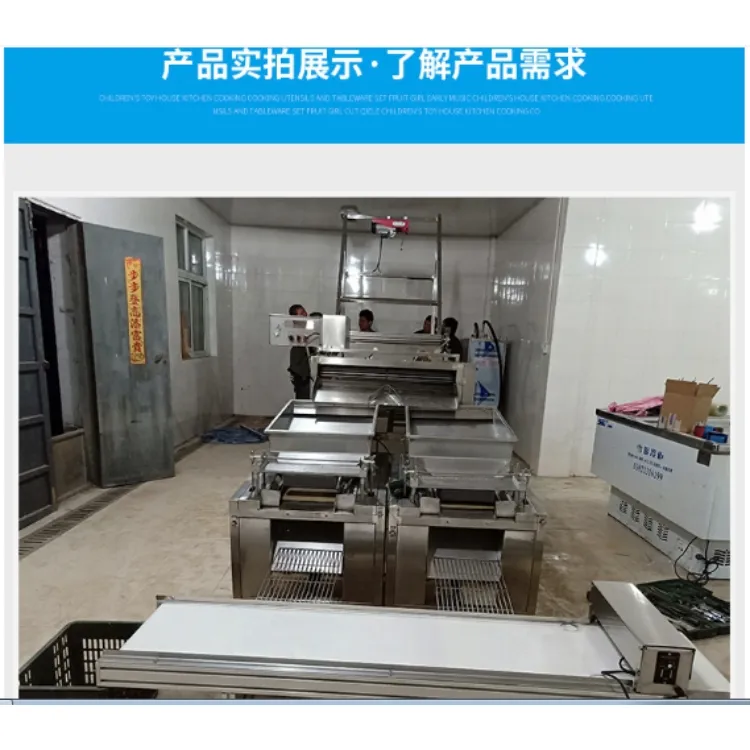

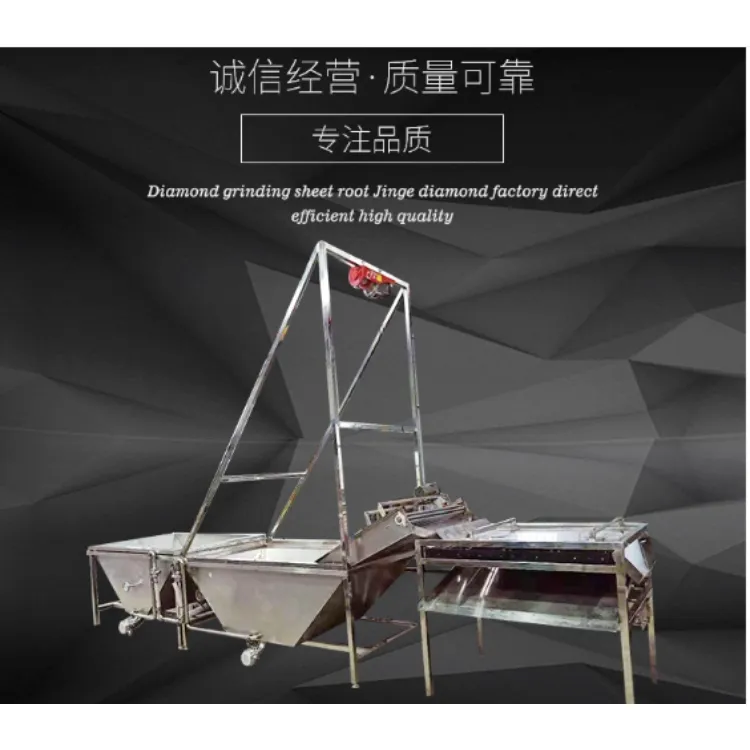

The quail egg processing line is a comprehensive system that incorporates various equipment to streamline the processing of quail eggs. The line consists of quail egg low temperature soaking equipment, an egg cooking machine, low temperature cooling equipment, a shell breaking machine, and a shelling machine. Additionally, the processing line can be customized with cleaning, drying, packaging, and other functions based on specific process requirements.

The quail egg processing line is a comprehensive system that incorporates various equipment to streamline the processing of quail eggs. The line consists of quail egg low temperature soaking equipment, an egg cooking machine, low temperature cooling equipment, a shell breaking machine, and a shelling machine. Additionally, the processing line can be customized with cleaning, drying, packaging, and other functions based on specific process requirements.

Purpose: To improve egg yolk eccentricity and enhance the yield of finished products.

Process: Cooked quail eggs undergo cooling with cold water.

Purpose: Shell breaking treatment is performed before peeling to facilitate the subsequent peeling process.

Process: Removal of the eggshell.

Function: Manual selection of bad eggs, washing, and transportation of the finished eggs.

Мощность: 370 Вт

Dimensions: 1000*900*2000 mm

Weight: 240 KG

Power: 750W

Dimensions: 2600*1080*2700 mm

Weight: 240 KG

Power: 750W

Dimensions: 3000*800*1260 mm

Weight: 200 KG

Power: 550W

Dimensions: 1100*650*900 mm

Weight: 80 KG

Power: 140W

Dimensions: 1500*300*500 mm

Weight: 60 KG

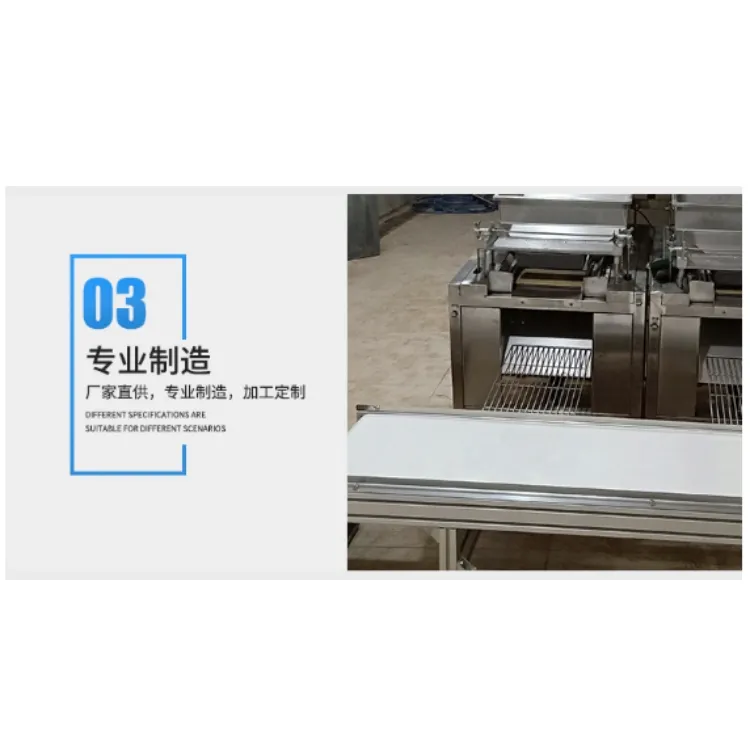

Enables fast and efficient cleaning, shell separation, and egg processing, reducing labor costs.

Does not damage the egg surface, ensuring high efficiency and a low damage rate.

Lightweight design for easy movement, coupled with a durable and aesthetically pleasing construction.

Stainless steel manufacturing for easy operation, low noise, and longevity.

Energy saving and environmentally friendly design, with low maintenance requirements, making it cost effective in the long run.