Address:China

Working time :Monday to Friday: 7am to 7pm

Weekends: 10am to 5pm

Address:China

Working time :Monday to Friday: 7am to 7pm

Weekends: 10am to 5pm

Quail eggs, known for their miniature size and delicate flavor, are a popular delicacy in various cuisines worldwide. In industrial settings, the efficient processing of quail eggs is crucial to meet the demands of restaurants, food manufacturers, and more. The Industrial Quail Egg Shelling and Peeling Machine represents the pinnacle of technology in quail egg processing. In this comprehensive guide, we will explore the intricacies of these innovative machines, including their features, working principles, advantages, and applications, shedding light on their critical role in streamlining quail egg processing operations.

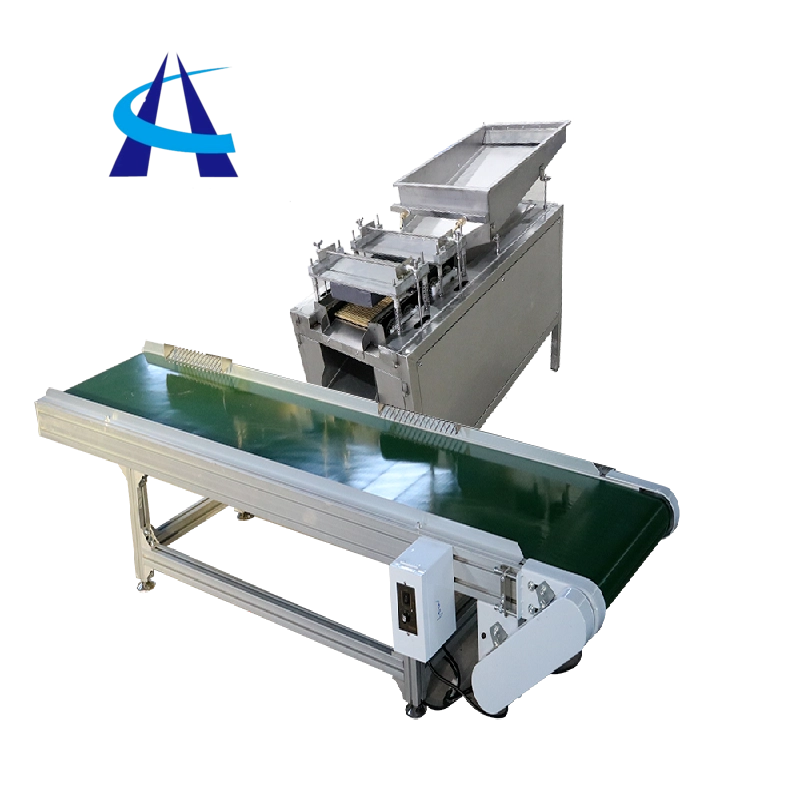

The Industrial Quail Egg Shelling and Peeling Machine is a cutting-edge apparatus designed to peel and shell quail eggs efficiently. This machine features a unique design that combines rolling rubber friction and the impact of strong water to mimic the principle of manual shelling. The result is a high peeling rate and low damage rate, ensuring that quail eggs are processed with precision and care. These machines are constructed with high-quality components, including importation parts, and boast a user-friendly PLC touch screen controller system that allows for the adjustment of working speed and independent control of each equipment component.

1. Unique Peeling System: The new design peeling system offers a high peeling rate and minimizes breakage, ensuring that quail eggs are processed with care and precision.

2. High-Quality Components: The machine incorporates imported parts, guaranteeing high quality and durability in its construction.

3. PLC Touch Screen Controller: The entire production equipment is equipped with a PLC touch screen controller system, enabling the adjustment of working speed and independent control of each equipment component.

4. High Efficiency: One set of quail egg peeler machines can replace the manual labor of 3-4 individuals, significantly improving operational efficiency.

5. Food-Grade Construction: The entire equipment is constructed from food-grade 304 stainless steel, ensuring hygiene and durability.

6. Easy Integration: The machine can be seamlessly integrated into a complete production line, offering an easy and automatic operation that streamlines the quail egg processing journey.

7. Customization: The flexibility of the machine allows for customization based on individual needs, enabling tailored solutions for various production requirements.

Quail Egg Peeling Machine operates through a series of well-defined stages to achieve the efficient processing of quail eggs. Let’s delve into the working process in detail:

1. Unique Peeling System: The machine’s new design peeling system combines rolling rubber friction and the impact of strong water to mimic the principle of manual shelling. This unique approach results in a high peeling rate and low damage rate, ensuring the quail eggs are processed with precision.

2. Water Tank Feeding: The equipment is equipped with a water tank feeding system that facilitates the orderly entry of quail eggs. This feature ensures that quail eggs are fed more evenly and consistently, setting this machine apart from other peeling machines.

3. Multi-Column Transport: Quail eggs are transported using a multi-column system, further enhancing the machine’s ability to process quail eggs efficiently.

4. High-Precision Control: The PLC touch screen controller system allows for precise control of the machine’s working speed, ensuring that the peeling and shelling process is tailored to the specific requirements of the quail eggs being processed.

Quail Bird Egg Peeler Machine offers numerous advantages that make it an indispensable asset in the food industry:

1. Precise Peeling: The unique peeling system results in a high peeling rate and minimal damage, ensuring that quail eggs are processed with care and precision.

2. Durability: The machine incorporates high-quality components, including importation parts, to guarantee its durability and longevity.

3. Control and Flexibility: The PLC touch screen controller system allows for precise control over the machine’s working speed and the independent control of each equipment component.

4. Operational Efficiency: The machine’s efficiency is evident in its ability to replace the manual labor of 3-4 individuals, making it a cost-effective and labor-saving solution.

5. Hygienic Design: Constructed from food-grade 304 stainless steel, the machine ensures impeccable hygiene standards.

6. Seamless Integration: The machine can be seamlessly integrated into complete production lines, offering a streamlined and automatic operation.

7. Customization: The flexibility of the machine allows for customization to meet specific production requirements, providing tailored solutions for individual needs.

Quail Bird Egg Peeler Machine finds applications in various sectors and industries, including:

1. Restaurants and Food Service: These machines streamline quail egg processing in restaurants, ensuring efficient preparation for a variety of dishes.

2. Food Manufacturers: Food manufacturers benefit from the efficiency and precision of these machines, enabling the production of quail egg-based products on a larger scale.

3. Culinary Education: Culinary schools and educational institutions utilize these machines for teaching and training purposes, providing students with hands-on experience in quail egg processing.

4. Culinary Enthusiasts: Home cooks and culinary enthusiasts who appreciate the delicate flavor of quail eggs can also benefit from these machines to enhance their culinary creations.

Frequently Asked Questions (FAQs)

1. How can I obtain more detailed information about China Quail Egg Peeling Machine

Answer: To receive comprehensive information about these machines, please initiate an inquiry, send an email, or contact us directly. Our team is prepared to provide official quotations and address your specific requirements.

2. How do I determine if a China Quail Egg Peeling Machine is suitable for my needs?

Answer: To assess the suitability of the machine for your specific requirements, please get in touch with us and provide detailed information about your production situation and needs. We will offer tailored recommendations to align with your demand.

3. How can I acquire a China Quail Egg Peeling Machine for my facility?

Answer: Once you confirm your order, we will generate a proforma invoice for payment. Subsequently, we will initiate preparations for the machine and arrange delivery to the location of your choice. We will also assist with exporting procedures, and upon arrival, we will provide all necessary clearance documents for customs.

4. Do you offer overseas engineering services for Industrial Quail Egg Shelling and Peeling Machines?

Answer: Yes, we do provide overseas engineering services. If you purchase the machine from us, we will send an engineer to your location for installation and training, ensuring that you can maximize the machine’s capabilities.

5. Can you customize Industrial Quail Egg Shelling and Peeling Machines to meet my specific requirements?

Answer: Certainly, we have the capability to customize the machine according to your specific needs. If you can provide drawings and precise technical data, we will tailor the equipment to align with your unique demands.

6. What kind of after-sale service do you offer for Industrial Quail Egg Shelling and Peeling Machines?

Answer: Our machines come with a one-year warranty that covers any malfunctions. In addition to this, we provide lifetime technical support. If any issues arise during your future usage, simply document the problem with photos and videos, and we will respond within 24 hours, working diligently to address and resolve your concerns.

Conclusion

Industrial Quail Egg Shelling and Peeling Machines are at the forefront of innovation in quail egg processing. Their unique design and precision make them an invaluable asset in various industries, from restaurants and food manufacturers to culinary education and home kitchens. The advantages offered by these machines, such as high peeling rates, durability, and customization options, position them as essential tools in streamlining quail egg processing operations.

As the demand for quail eggs continues to grow, Industrial Quail Egg Shelling and Peeling Machines provide a testament to the innovative solutions available to meet the needs of the culinary world. Whether you are a professional chef, a food manufacturer, or a culinary enthusiast, these machines offer a gateway to enhanced quail egg culinary creations and streamlined production processes.