Description

Discover the epitome of innovation in egg processing with our Commercial Egg Peeling Machine – a specialized marvel designed for automatically shelling boiled chicken eggs. This cutting-edge machine boasts a host of features that make it the preferred choice for manufacturers producing boiled eggs, spiced eggs, and other egg products. Here’s a detailed description of this advanced egg peeling machine:

Introduction of Hen Egg Peeling Machine

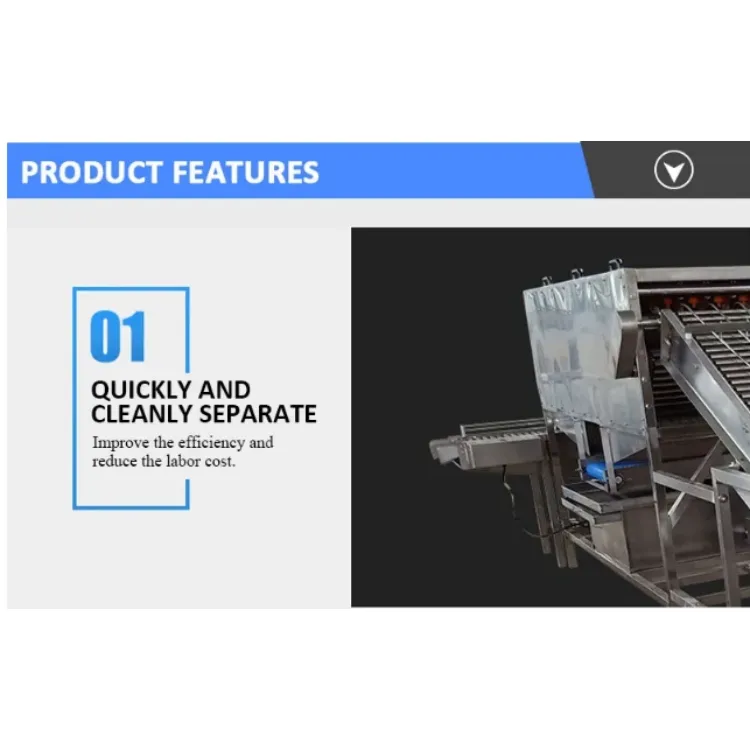

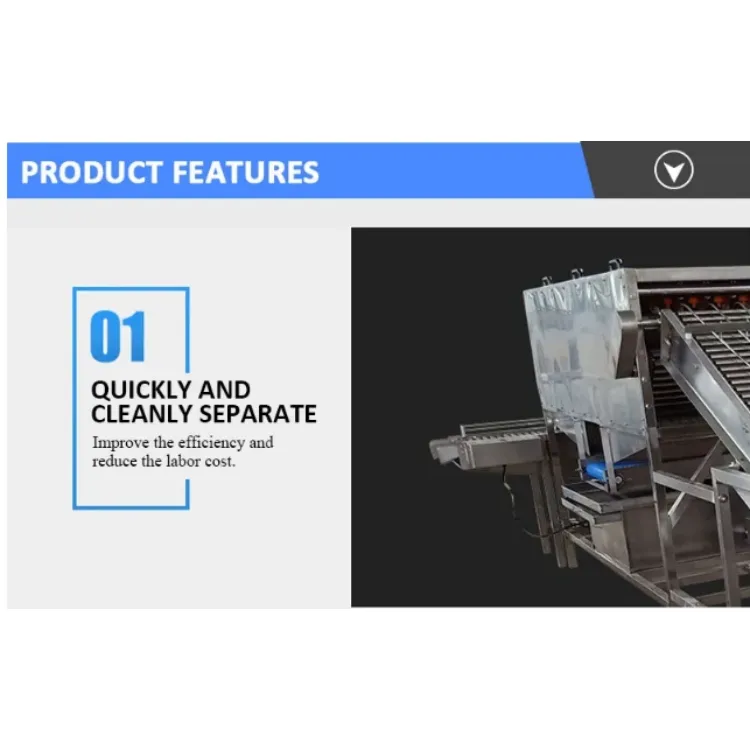

- This professionalchicken egg peeling machineexcels at fast and clean removal of boiled hen eggs’ shells.

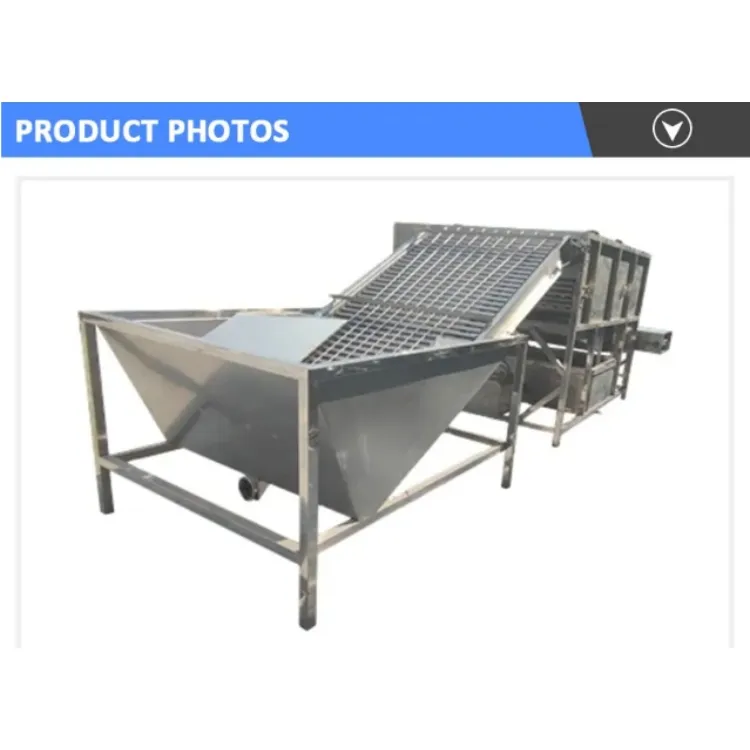

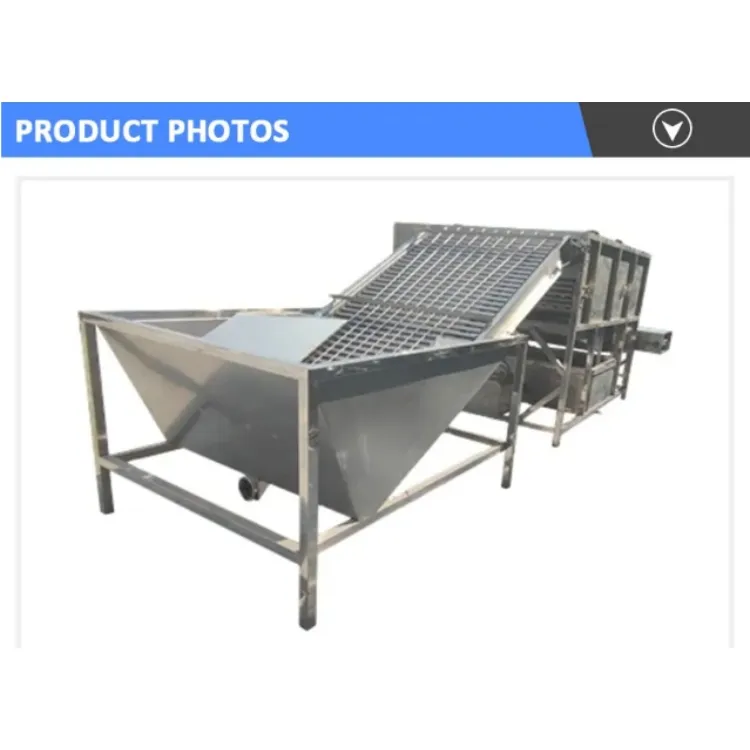

- Crafted from high-quality stainless steel, it adopts an import high-quality frequency conversion motor and durable rubber hose, ensuring a long service life and adherence to health standards.

- The machine features an automatic feeding system, reducing hand-feed waste and saving manpower.

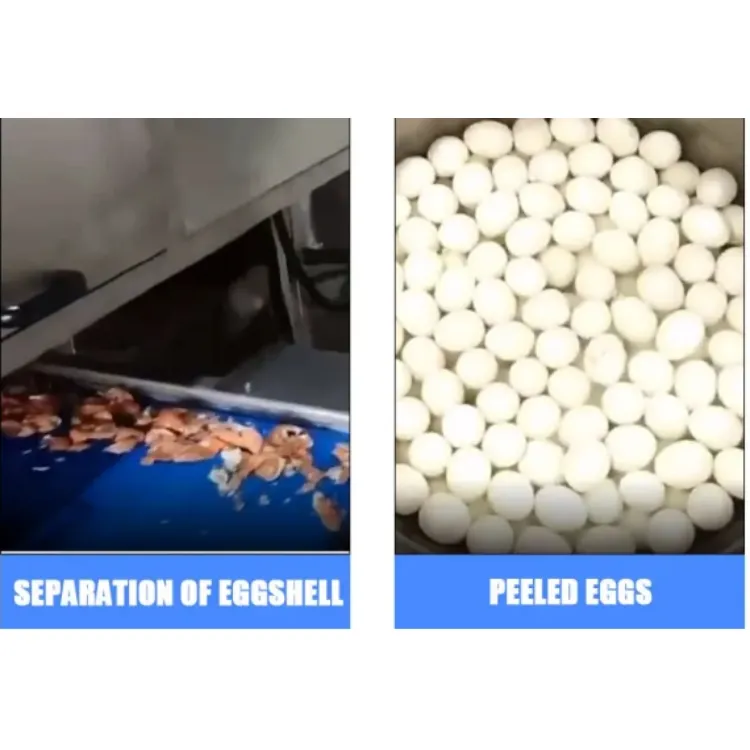

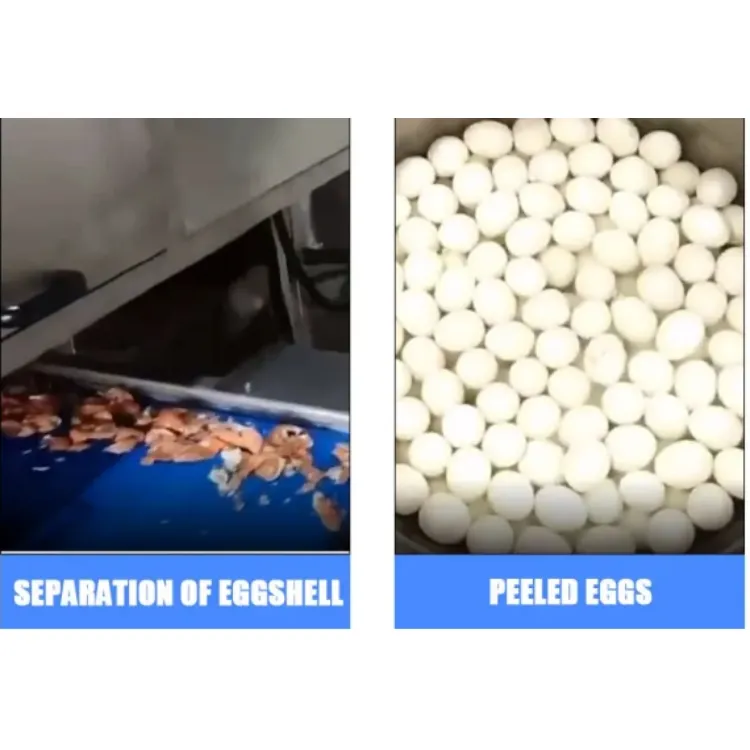

- Automatic collection and disposal of eggshells ensure the quality and cleanliness of the hen eggs.

Features of Hard-Boiled Egg Peeler Machine

- High efficiency and low breakage rate.

- Stainless steel material meeting food hygiene standards.

- Special design, compact structure, and beautiful appearance.

Product Advantages

- Premium Construction Crafted from food-grade stainless steel, the machine guarantees durability, safety, and healthiness, ensuring that the eggs remain uncontaminated.

- Ingenious Design With a compact structure and a special roller design, the machine handles eggs delicately, preventing any harm to the eggs during the peeling process.

- Efficiency and Precision:The machine operates with high efficiency and maintains a low breakage rate, making it a reliable choice for preserving the integrity of eggs during the peeling process.

- User-Friendly Features :Automatic feeding and discharging mechanisms streamline the process, saving on labor costs. The machine is designed for easy cleaning and effortless mobility.

- Automatic Eggshell Collection: A unique feature that automatically collects eggshells, further enhancing operational efficiency and cleanliness.

- Technological Superiority :Considered the most advanced peeling eggs equipment in China, it embodies the latest advancements in egg peeling technology.

Machinery Specifications

Capacity :5000-10000pcs/h

Function: Hard-boiled egg peeling, shelling, and cleaning

Application :Ideal for boiled eggs

Material :304 Stainless Steel

Keywords :Egg peeler, egg sheller, boiled egg shell removal machine

Feature :Easy to operate

Advantage :High efficiency

Automatic Egg Sheller Usage Guide

- For optimal results, use fresh eggs aged 2-3 days in summer or 4-5 days in winter.

- Heat water to about 85 degrees and pour it into the eggs, stirring and boiling with high heat.

- After boiling, remove damaged eggs. Simmer gently for 15-20 minutes, then cool the eggs in cold water.

- After 15 minutes, pour the cooled eggs into the egg shelling machine, soaking them in cold water.

- Connect the power supply and water supply, starting with the pump and then the machine, while controlling the water flow moderately.

Embrace the future of egg processing with our state-of-the-art Commercial Egg Peeling Machine – where efficiency, precision, and technological superiority converge to redefine your egg processing experience.