주소: 중국

근무 시간 :월요일~금요일: 오전 7시~오후 7시

주말 주말: 오전 10시 ~ 오후 5시

주소: 중국

근무 시간 :월요일~금요일: 오전 7시~오후 7시

주말 주말: 오전 10시 ~ 오후 5시

To use the Chicken Egg Peeler Machine, follow these steps:

Size : 2800*900*1210 MM

Material The entire machine is constructed from 304 stainless steel. The panel thickness is 1.2mm, and the bracket thickness is 3.0mm.

Output Capable of peeling5,000 pieces per hour.

Voltage 220V, Power: 3.5KW

Weight 1800Kg

Turn on the water source, power supply and turn on the delivery switch

Pour the cooked eggs into the water tank and adjust the lifting speed(There is a frequency converter in the distribution box that can be adjusted)

Turn on the shell-crushing switch, turn on the water pump switch, and adjust the speed of the shell-crushing so that the shells can be sufficiently crushed (there is a speed regulator in the distribution box that can be adjusted)

Adjust the water flow. When peeling eggs, water is needed to rinse the eggs, which can more effectively remove the eggshells on the surface of the eggs.

Adjust the schedule of shelling (the speed of the hose determines whether the shelling is clean, and it is not easy to be too fast)

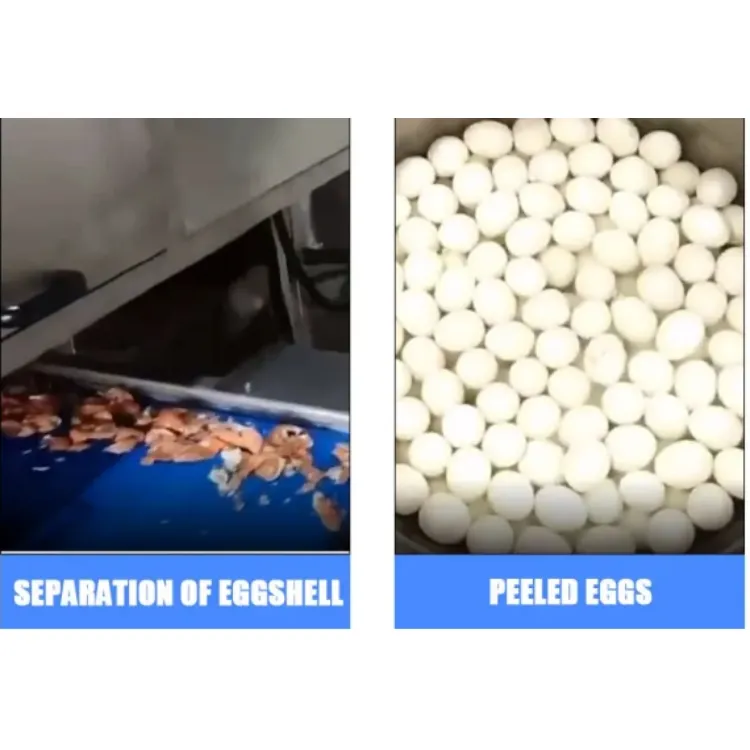

Turn on the eggshell transport switch and transport the eggshells out.

Turn on the egg selection transport switch and start selecting bad eggs and eggs that have not been shelled.

In summary, the chicken egg peeler machine offers efficiency, precision, and durability in the egg processing industry, making it a valuable asset for businesses involved in the production of boiled and processed eggs.