Alamat: Tiongkok

Waktu kerja: Senin hingga Jumat: 7 pagi hingga 7 malam

Akhir pekan: Pukul 10.00 hingga 17.00

Alamat: Tiongkok

Waktu kerja: Senin hingga Jumat: 7 pagi hingga 7 malam

Akhir pekan: Pukul 10.00 hingga 17.00

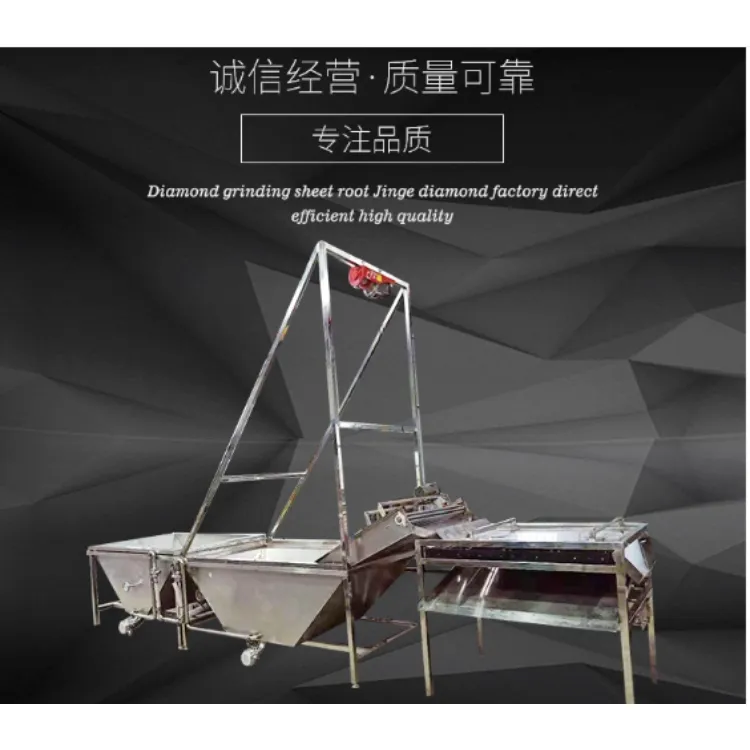

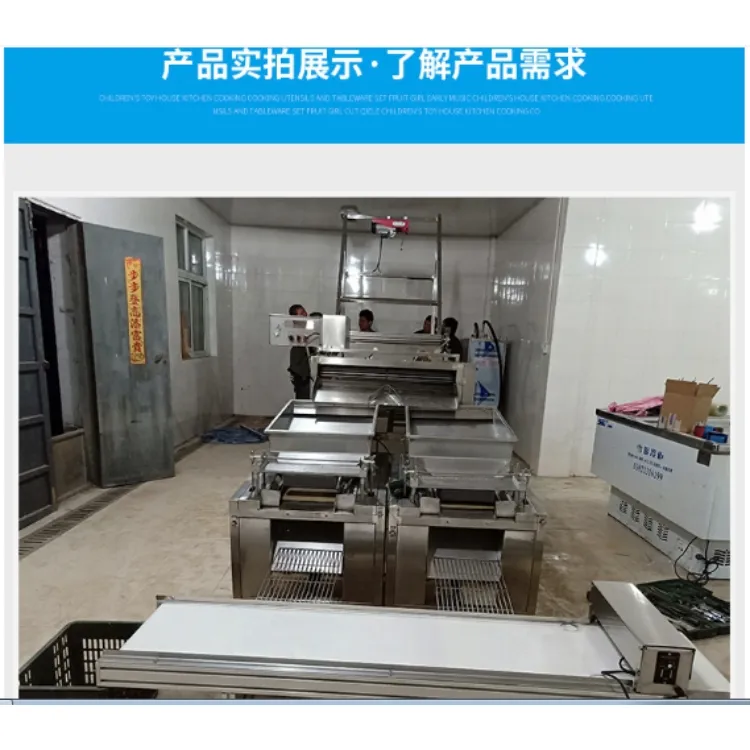

The quail egg processing line is a comprehensive system that incorporates various equipment for handling quail eggs. This includes quail egg low-temperature soaking equipment, an egg cooking machine, low-temperature cooling equipment, a shell-breaking machine, and a shelling machine. Additionally, the processing line can be customized with cleaning, drying, packaging, and other functions based on specific process requirements.

Quail Egg Ppengolahan Plants

Quail Egg Processing Plants Introduction:

The quail egg processing line is a comprehensive system that incorporates various equipment for handling quail eggs. This includes quail egg low-temperature soaking equipment, an egg cooking machine, low-temperature cooling equipment, a shell-breaking machine, and a shelling machine. Additionally, the processing line can be customized with cleaning, drying, packaging, and other functions based on specific process requirements.

Function of Quail Egg Ppengolahan Plants :

– Purpose: Improve egg yolk eccentricity and enhance the yield of finished products.

– Method: Cooked quail eggs undergo cooling with cold water.

– Purpose: Shell-breaking treatment is applied before peeling to facilitate the subsequent peeling process.

– Process: Remove the eggshell to obtain the peeled eggs.

– Function: Manually select defective eggs and wash and transport the finished eggs.

– Quail Egg Cooking Machine:

– Power: 370W

– Dimensions: 1000*900*2000 mm

– Weight: 240 KG

– Cooling Machine:

– Power: 750W

– Dimensions: 2600*1080*2700 mm

– Weight: 240 KG

– Quail Egg Breaking Machine:

– Power: 750W

– Dimensions: 3000*800*1260 mm

– Weight: 200 KG

– Quail Egg Peeling Machine:

– Power: 550W

– Dimensions: 1100*650*900 mm

– Weight: 80 KG

– Peeled Eggs Conveyor:

– Power: 140W

– Dimensions: 1500*300*500 mm

– Weight: 60 KG

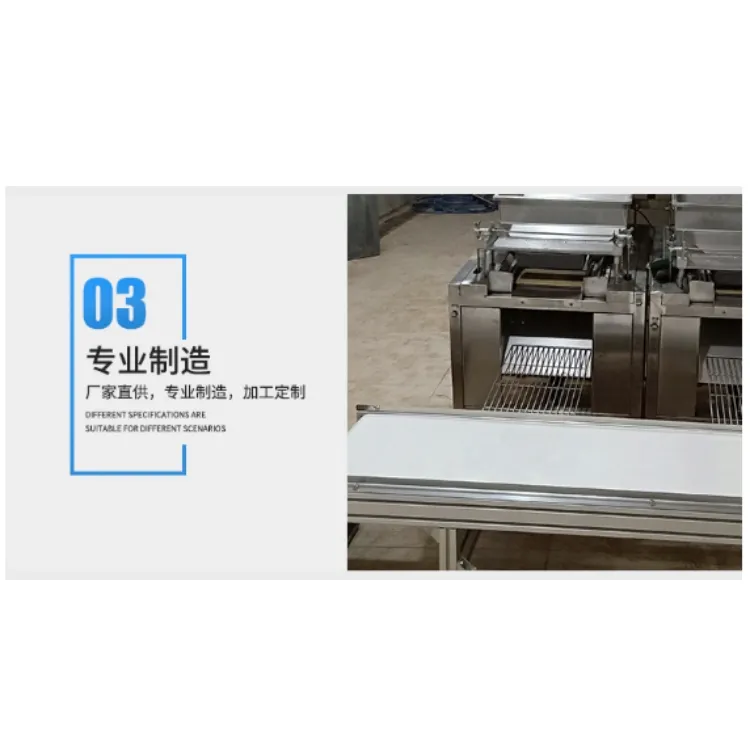

– Fast and efficient egg cleaning, shell separation, improving efficiency, and reducing labor costs.

– The design ensures that the egg surface is not damaged, resulting in high efficiency and a low damage rate.

– The processing line is designed with lightweight materials, making it easy to move, aesthetically pleasing, and durable.

– The equipment is constructed with stainless steel, ensuring easy operation, low noise, and longevity.

– The system is energy-efficient and environmentally friendly, with a long life span and low maintenance requirements, making it cost-effective.