Adresse : Chine

Temps de travail :du lundi au vendredi : de 7h à 19h

Le week-end : 10h00 à 17h00

Adresse : Chine

Temps de travail :du lundi au vendredi : de 7h à 19h

Le week-end : 10h00 à 17h00

The quail egg peeler machine is a reliable and efficient solution for large-scale peeling of quail eggs. With its stainless steel construction, automatic operation, and easy maintenance, it ensures a stable and clean peeling process. The machine also preserves the quality and taste of quail eggs while reducing labor costs. Additionally, it is made of hygienic material and comes with complementary equipment for enhanced peeling. Suitable for various industries and snack food applications, this machine is a valuable asset.

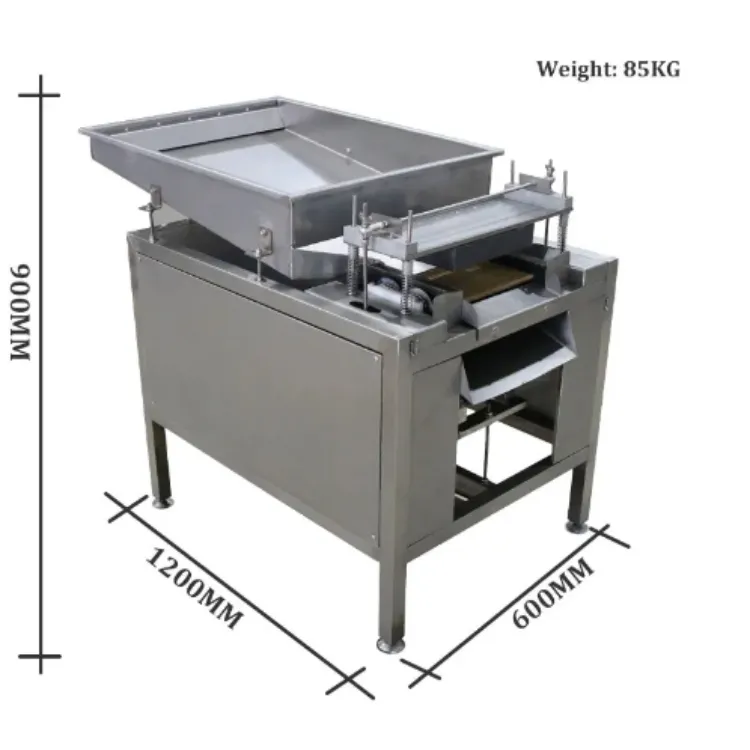

| HT-HQ1 | 50-100kg/h

(about 4,000 pieces) |

760mm×410mm×810mm | 52kg |

| HT-HQ2 | 150-300kg/h

(about30,000pieces) |

1200mm×650mm×800mm | 87kg |

The automatic quail egg peeler operates on a simple yet effective mechanism driven by the rotation of a motor. The process involves several key components working in tandem to achieve efficient quail egg shelling:

The machine is equipped with a motor that drives the entire shelling process. As the motor rotates, it initiates the mechanical movements required for effective peeling.

The motor’s rotational force is transmitted to a gear mechanism within the machine. Gears play a crucial role in translating the motor’s rotational energy into controlled movements necessary for the peeling operation.

The gear mechanism is connected to a sponge pad, which moves in response to the rotation of the gears. This up-and-down movement of the sponge pad is a pivotal part of the peeling process.

Simultaneously, the gear mechanism also drives the rotation of a hose. This rotating hose adds another dimension to the peeling action, contributing to the overall effectiveness of the process.

The coordinated movement of the sponge pad and rotating hose generates friction against the quail egg’s surface. This friction is essential for tearing the shell from the egg, ensuring a clean and efficient peeling outcome.

The combined action of the sponge pad moving up and down and the rotating hose creates the necessary force to tear the quail eggshell. As a result, the shell is effectively removed from the surface of the egg, leaving behind a peeled quail egg.

This innovative and mechanical approach ensures a reliable and automated quail egg peeling process. By leveraging motor-driven mechanisms, the machine achieves consistent and high-quality results, contributing to increased efficiency in large-scale quail egg processing operations.

Éplucheuse automatique d'œufs de caille Caractéristiques

Cette machine convient aux industries de transformation des œufs de caille épicés et des œufs de caille bouillis, ainsi qu'à d'autres aliments à grignoter contenant des œufs de caille.