Description

Size : 2800*900*1210 MM

Material The entire machine is constructed from 304 stainless steel. The panel thickness is 1.2mm, and the bracket thickness is 3.0mm.

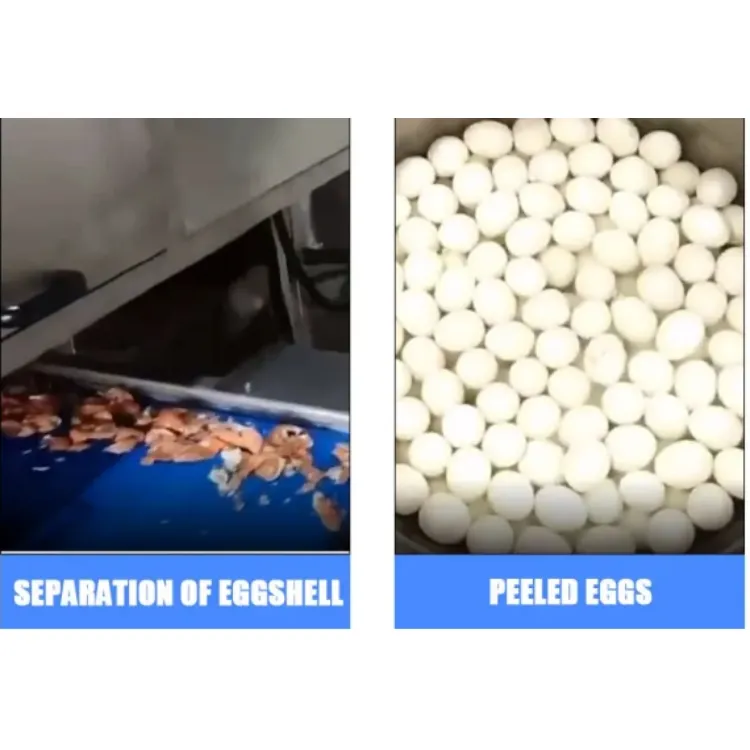

Output Capable of peeling5,000 pieces per hour.

Voltage 220V, Power: 3.5KW

Weight 1800Kg

Chicken Egg Péeler Mmachine Caractéristiques du produit

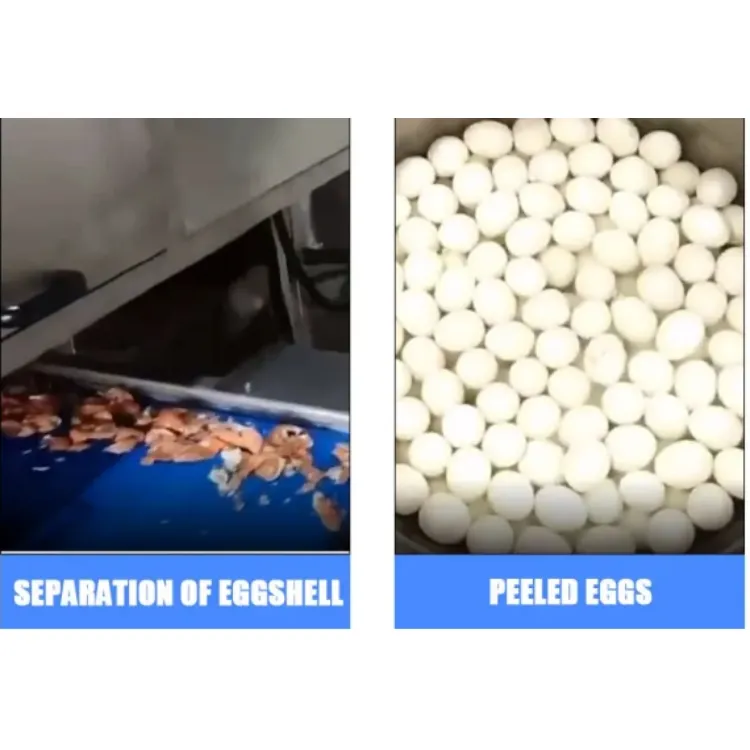

- Efficient Separation :The épluche-œufs can quickly and cleanly separate eggs from their shells, significantly improving efficiency and reducing labor costs in the egg processing process.

- Gentle on Eggs: This machine ensures that the surface of the egg remains undamaged during the peeling process. It achieves high efficiency with a low damage rate, preserving the overall quality of the peeled eggs.

- Stainless Steel Construction: The egg peeler is constructed using stainless steel, providing durability, ease of operation, and low noise levels. The use of stainless steel ensures hygiene and facilitates easy cleaning of the equipment.

Chicken Egg Péeler Mmachine usage steps

Turn on the water source, power supply and turn on the delivery switch

Pour the cooked eggs into the water tank and adjust the lifting speed(There is a frequency converter in the distribution box that can be adjusted)

Turn on the shell-crushing switch, turn on the water pump switch, and adjust the speed of the shell-crushing so that the shells can be sufficiently crushed (there is a speed regulator in the distribution box that can be adjusted)

Adjust the water flow. When peeling eggs, water is needed to rinse the eggs, which can more effectively remove the eggshells on the surface of the eggs.

Adjust the schedule of shelling (the speed of the hose determines whether the shelling is clean, and it is not easy to be too fast)

Turn on the eggshell transport switch and transport the eggshells out.

Turn on the egg selection transport switch and start selecting bad eggs and eggs that have not been shelled.

Boiled Egg Peeling Technique

- For optimal results, use fresh eggs aged 2-3 days in summer or 4-5 days in winter.

- Heat water to about 85 degrees and pour it into the eggs, stirring and boiling with high heat.

- After boiling, remove damaged eggs. Simmer gently for 15-20 minutes, then cool the eggs in cold water.

- After 15 minutes, pour the cooled eggs into the egg shelling machine, soaking them in cold water.

- Connect the power supply and water supply, starting with the pump and then the machine, while controlling the water flow moderately.

Chicken Egg Péeler Mmachine Shipping and Ordering Information

- Loading Container :The egg peeler can be loaded into containers at various locations, including Qingdao, Shanghai, Ningbo, Tianjin, Guangzhou, etc.

- Méthodes d'expédition :Nous proposons plusieurs méthodes d'expédition, notamment le service de messagerie, le transport aérien et le transport maritime, afin de répondre aux besoins de nos clients.

- Options de commande :L'entreprise peut accepter des commandes pour des conteneurs complets ou des conteneurs plus petits, ce qui permet de répondre à différentes échelles de demande.

- Options de service :Nous proposons diverses options de service telles que EXW (Ex Works), FOB (Free On Board), CIF (Cost, Insurance, Freight), CNF (Cost and Freight), Door to Door, etc.

- Shipping Company Selection :We ensure the selection of the most economical and reliable shipping company to ensure timely delivery of the egg peeler machine.

- Informations de suivi Une fois l'envoi expédié, l'entreprise fournit un numéro de suivi au client, ce qui lui permet de suivre l'état de sa commande pendant le transport.

In summary, the chicken egg peeler machine offers efficiency, precision, and durability in the egg processing industry, making it a valuable asset for businesses involved in the production of boiled and processed eggs.