Adresse : Chine

Temps de travail :du lundi au vendredi : de 7h à 19h

Le week-end : 10h00 à 17h00

Adresse : Chine

Temps de travail :du lundi au vendredi : de 7h à 19h

Le week-end : 10h00 à 17h00

Machine à éplucher les oeufs pour les entreprises de production d'oeufs et les usines de transformation des aliments

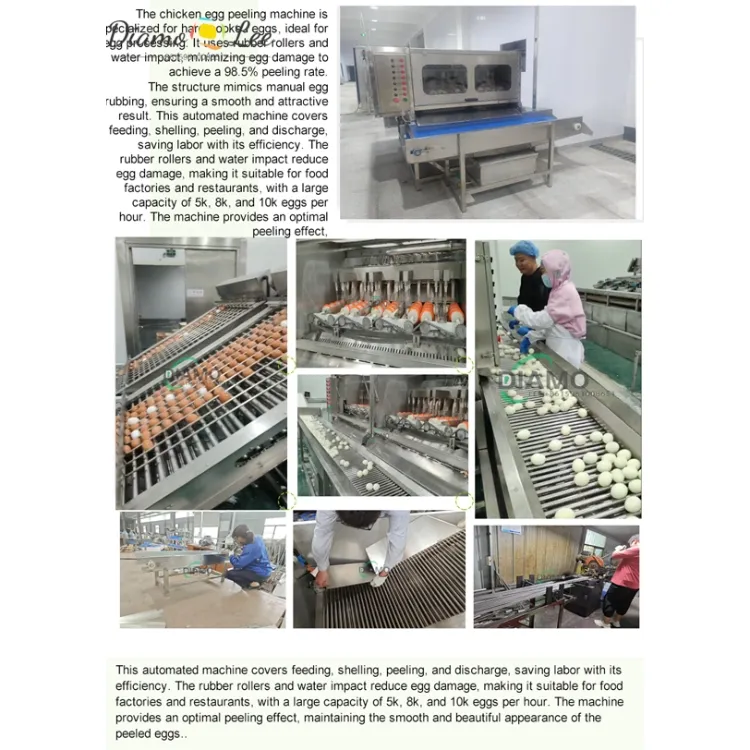

A specialized equipment designed for efficiently peeling hard-cooked chicken eggs, catering to various egg processing needs. Crafted with precision and efficiency in mind, this machine adopts rubber rollers and robust water impact, significantly reducing egg damage while ensuring a high peeling rate of up to 98.5%. Let’s delve into the details:

Les Machine à éplucher les œufs de poule mimics the manual egg rubbing process, resulting in easy and effective eggshell removal without damaging the egg surface, leaving behind smooth and beautiful peeled eggs.

Featuring automatic operation, the machine encompasses feeding, shelling, peeling, and discharge functions, streamlining the process and saving labor.

Constructed from full 304 stainless steel, the machine ensures durability, hygiene, and easy cleaning.

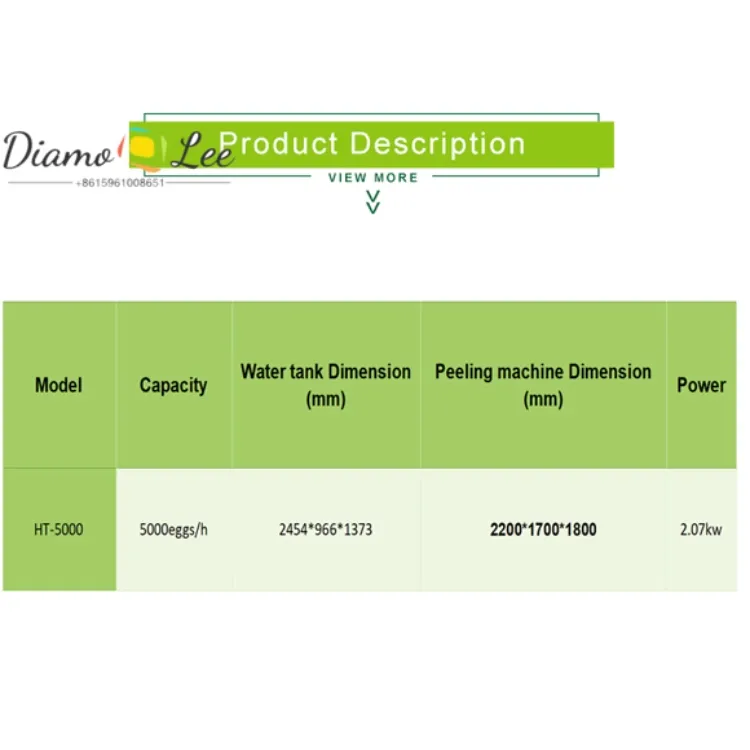

With a large capacity ranging from 5,000 to 10,000 eggs per hour, it is suitable for various food processing settings such as factories and restaurants.

The water tank feeder facilitates the cooling of boiled eggs and their seamless transfer to the peeling machine, enhancing efficiency.

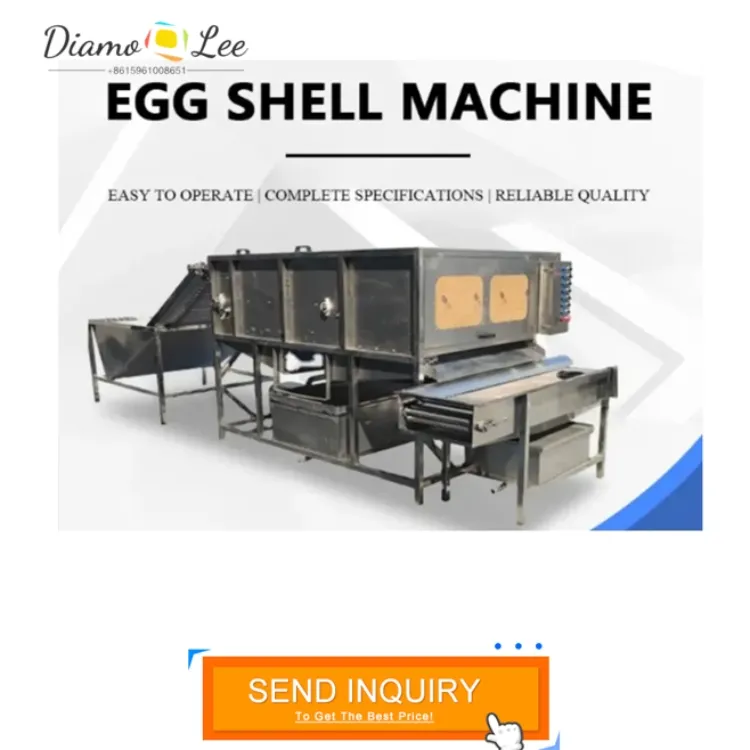

The egg peeling line consists of a water tank, egg peeling machine, and a conveyor for collecting peeled eggs while discarding defective ones.

Boiled eggs are cooled in the water feeding tank before being automatically conveyed to the shell cracking section.

The shelling process gently breaks the eggshell without causing damage.

In the peeling phase, cracked shells are removed under a water shower and latex tubing.

A collecting conveyor gathers the peeled eggs while discarding any imperfect ones.

Mimics manual egg rubbing for efficient peeling without surface damage.

Made of full 304 stainless steel for durability and hygiene.

Automatic operation with feeding, shelling, peeling, and discharge functions.

Utilizes rubber rollers and strong water impact to minimize egg damage.

Large capacity options available, suitable for various food processing settings.

Water recycling system for cost and resource efficiency.

Specialized machine for high-efficiency egg shelling with low breakage rates.

Constructed from 304 stainless steel, meeting hygiene standards.

Incorporates a water recycling system for energy efficiency.

Achieves over 98% peeling rate with minimal damage.

Compact design with smooth surface, suitable for various egg products.

For detailed information, please contact us directly for an official quotation.

Contact us with your requirements and production situation for tailored recommendations.

Upon order confirmation, we handle the delivery and exporting process, providing necessary documents for customs clearance.

Yes, we provide engineer overseas service for installation and training.

We offer customization based on provided drawings and technical data.

Our warranty covers one year, with lifetime technical support for any future issues. Simply reach out to us with photos or videos, and we’ll promptly assist you.

Whether for food factories, restaurants, or other egg processing facilities, our Chicken Egg Peeling Machine offers unparalleled efficiency, quality, and reliability, ensuring seamless egg peeling operations for various applications.