Adresse : Chine

Temps de travail :du lundi au vendredi : de 7h à 19h

Le week-end : 10h00 à 17h00

Adresse : Chine

Temps de travail :du lundi au vendredi : de 7h à 19h

Le week-end : 10h00 à 17h00

Eggs are a staple in countless culinary creations, from the most delicate pastries to hearty omelets and beyond. The process of separating egg whites and yolks, however, can be a laborious task, especially in high-volume production settings like bakeries and cake factories. To streamline this process, an ingenious piece of machinery has emerged – the Automatic Egg Cracking Machine, also known as the Egg Separator. In this article, we will explore the intricate workings of this revolutionary appliance, its various features, and the range of industries it benefits.

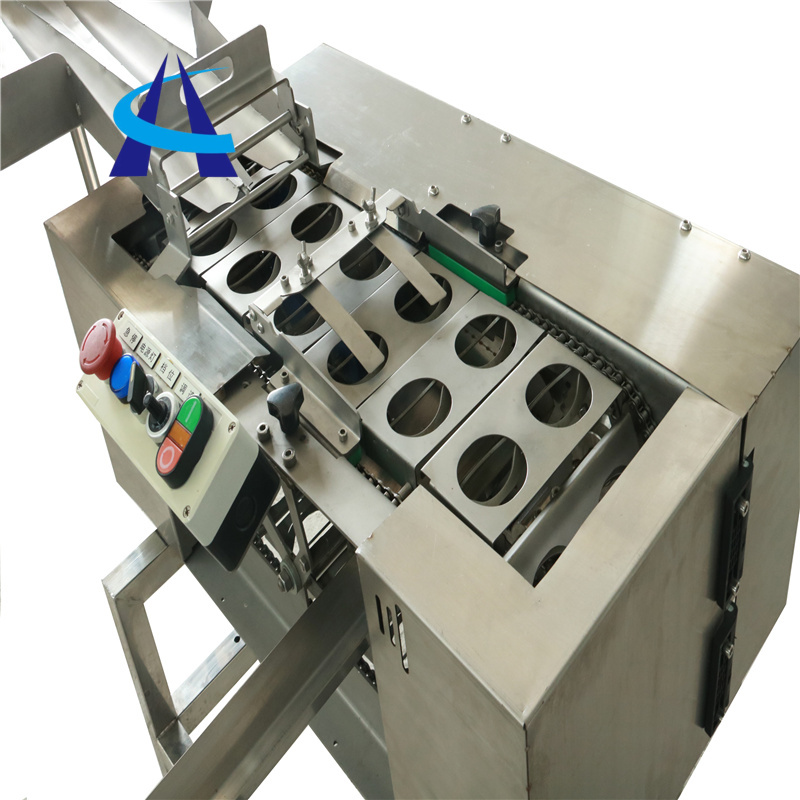

The Automatic Machine à craquer les œufs is a marvel of engineering designed to facilitate the efficient production of fresh egg liquid while separating egg whites and yolks with precision. Its key features make it an indispensable tool for industries reliant on large quantities of eggs.

1.Eggshell Opening and Disposal

One of the primary functions of the egg cracking machine is to open the eggshells. As eggs are loaded into the machine, it delicately cracks each shell, allowing the egg white and egg yolk to flow out into a designated container. Simultaneously, the eggshell itself is separated and falls into a separate container for disposal. This dual-action process ensures that no part of the egg is wasted.

2. Adjustable Machine à casser les œufs

The machine is equipped with a special egg beater whose height can be adjusted according to the size of the eggs being processed. This feature is crucial in ensuring that eggs of various sizes are opened uniformly. By adapting to the specific dimensions of each egg, the machine guarantees that every egg is cracked open without fail.

3. Touch Screen Control

The Automatic Machine à craquer les œufs incorporates user-friendly touch screen controls. This technology not only simplifies operation but also offers a range of functionalities. Users can monitor the number of eggs processed, track the egg flow speed, and gain valuable insights into the machine’s performance in real-time.

4. Continuous Eggshell Breaking Function

The machine’s continuous eggshell breaking function is a groundbreaking innovation. It emulates the manual process of cracking eggs without any risk of cross-contamination. Unlike manual egg breaking, where the liquid may come into contact with broken eggshell pieces, this machine ensures a high degree of hygiene by separating the eggshell from the liquid, leaving no room for contamination.

5. Continuous Separation of Egg White and Yolk

Another remarkable feature of the Separation of Egg White and Yolk is its continuous separation of egg whites and yolks. This process employs the gap separation method, which effectively divides the egg whites and yolks, directing them into their respective containers. For added convenience, the machine can be customized to accommodate specific separation requirements.

The versatile Automatic Egg Breaker Machine finds its application across various industries, transforming the way eggs are handled and processed. Its efficiency and hygiene benefits make it an invaluable addition to the following production enterprises:

1. Bakery

In bakeries, the Egg Breaker Machine enhances the efficiency of production by streamlining the process of handling and cracking eggs. Whether preparing batches of pastries, bread, or cakes, this machine ensures that eggs are opened without any risk of contamination, contributing to the production of safe and delicious baked goods.

2. Cake Factory

Cake factories rely on the precision and consistency of egg separation to create a wide range of delectable cakes. Egg Breaker Machine eliminates the need for manual labor in egg handling, ensuring that each cake is made with perfectly separated egg whites and yolks. This level of quality control is essential for creating cakes that meet high standards of taste and appearance.

3. Egg Pastry Production Enterprises

Enterprises specializing in egg pastries, such as quiches, tarts, and custard desserts, depend on the accuracy of egg separation. Egg Breaker & Yolk Separator Machine offers an efficient solution to these businesses, providing a consistent and sanitary method for breaking eggs and separating their contents.

To appreciate the full scope of the Egg Breaker & Yolk Separator Machine ‘s capabilities, it’s essential to delve into its technical specifications:

– Production Name: Egg Separator

- Tension : 220V

- Puissance : 500W

– Capacity: 6000 pieces per hour

– Machine Material: Stainless Steel

– Machine Size: 1700 x 1100 x 1100 mm

– Machine Weight: 200 kg

The machine’s production name, “Egg Separator,” underscores its primary function as an egg processing device. The voltage requirement of 220V makes it suitable for a wide range of electrical setups, while the power rating of 500W ensures efficient operation. With a remarkable capacity of 6000 pieces per hour, it is well-suited for high-volume production environments. The stainless steel construction guarantees durability and easy maintenance, making it a long-lasting investment for any business. The compact machine size and manageable weight make it easy to integrate into existing production lines.

Egg Breaker & Yolk Separator Machine offers a multitude of advantages to businesses operating in egg-based industries. These benefits extend far beyond convenience, making it a transformative asset in modern food production.

1. Enhanced Efficiency

The machine’s ability to process up to 6000 eggs per hour is a game-changer for businesses where time is of the essence. It significantly speeds up the egg handling process, allowing for greater productivity and faster order fulfillment. This increased efficiency can lead to higher profits and customer satisfaction.

2. Consistency

Egg separation and eggshell cracking require a high level of precision to ensure the quality of the final product. Egg Breaker & Yolk Separator Machine excels in providing consistent results, eliminating human error and variations in egg processing. This uniformity is vital in producing baked goods and dishes of consistent taste and texture.

In food production, maintaining hygiene is paramount. Traditional manual egg cracking can lead to cross-contamination if not executed with utmost care. The machine’s continuous eggshell breaking and separation functions eliminate the risk of contamination, ensuring that the egg liquid remains uncontaminated by broken shell fragments.

Cost Savings

While investing in a Commercial Egg Breaking Machine may initially seem like a significant expense, it is a cost-effective choice in the long run. By reducing the need for manual labor and minimizing egg wastage, businesses can save money over time. The machine also requires minimal maintenance, further reducing operational costs.

The machine’s adjustable egg beater and the option to install an egg white and egg yolk separation device allow for customization to meet specific production requirements. This adaptability ensures that the machine can seamlessly integrate into different production processes and adapt to various egg specifications.

6. Quality Control

Consistency in egg separation and eggshell cracking directly impacts the quality of the final product. The Commercial Egg Breaking Machine offers an unprecedented level of quality control, allowing businesses to maintain high product standards, meet customer expectations, and build a reputation for excellence.

7. Sustainability

The machine’s efficient eggshell separation and disposal contribute to sustainable practices in food production. By reducing eggshell waste and the risk of contamination, businesses can minimize their environmental impact and improve their sustainability credentials.

8. Labor Savings

One of the most significant advantages of the Commercial Egg Breaking Machine is its ability to reduce the labor required for egg processing. This is especially valuable in industries with high production demands, where manual egg cracking can be time-consuming and physically taxing. By automating the process, businesses can reallocate their workforce to more value-added tasks, such as recipe creation, quality control, and customer service.

The Importance of Egg Handling in Food Production

Eggs are a crucial ingredient in a wide array of food products, ranging from baked goods to sauces, custards, and more. Achieving the desired consistency and quality of these products relies heavily on the precision with which eggs are handled and separated. The Automatic Egg Cracking Machine addresses several key concerns in the food production industry.

1. Food Safety

Ensuring food safety is paramount in any food production facility. Eggs are susceptible to contamination from pathogens such as Salmonella. Manual egg cracking carries a risk of shell fragments contaminating the egg liquid, posing a threat to consumer health. Egg Breaking And Separating Machine ‘s hygienic design reduces this risk, contributing to the safety of the final products.

2. Consistency and Quality

Many recipes, especially in the baking industry, require precise measurements and ingredient consistency. Any deviation from the desired egg-to-liquid ratio can result in products that do not meet quality standards. By automating egg separation, the machine ensures that every batch maintains the same consistency, ultimately leading to higher-quality products.

3. Efficiency and Productivity

In a competitive market, businesses must find ways to streamline their production processes while maintaining high standards. The Automatic Egg Breaking And Separating Machine enhances both efficiency and productivity, allowing companies to meet growing demand without compromising on the quality of their products.

4. Cost Management

Effective cost management is essential for the long-term sustainability of any business. By reducing labor costs and minimizing egg wastage, the machine contributes to cost savings over time. Additionally, its ability to adapt to various egg sizes and types means that businesses can reduce overheads associated with multiple pieces of equipment.

5. Sustainability

The food industry is increasingly focused on sustainability and reducing waste. The Egg Breaking And Separating Machine plays a role in this endeavor by minimizing eggshell waste and promoting sustainable practices in the production process.

Case Studies: Success Stories of the Egg Breaking And Separating Machine

To illustrate the real-world impact of the Automatic Egg Cracking Machine, we will explore one case study of businesses that have embraced this technology and benefited from its advantages.

Case Study 1: A Bakery’s Quest for Efficiency and Consistency

Bakery “Sweet Delights” is known for its delectable pastries, cakes, and bread. As the demand for their products grew, so did the need for more efficient and consistent egg handling. Manual egg cracking had become a bottleneck in their production process, leading to inconsistencies in product quality.

The Solution:

After investing in an Automatic Egg Cracking Machine, “Sweet Delights” experienced a remarkable transformation in their operations. The machine’s ability to process thousands of eggs per hour allowed them to meet rising demand without compromising on quality. Their pastries and cakes now featured a uniform texture and flavor, making them even more popular among customers.