Dirección:China

Horario de trabajo :de lunes a viernes: de 7.00 a 19.00 horas

Fines de semana De 10.00 a 17.00 horas

Dirección:China

Horario de trabajo :de lunes a viernes: de 7.00 a 19.00 horas

Fines de semana De 10.00 a 17.00 horas

Quail eggs are available in three flavors: salt-baked, braised and pickled pepper. You can try this convenient and delicious snack when watching TV dramas. The quail eggs are slowly braised in high-concentration chicken broth, which not only tastes delicious, but also has a chewy texture. What kind of egg machinery are used to process such delicious quail eggs? Our braised crane quail egg production line not only saves you the trouble of shelling, but is also affordable.

A Quail Egg Brine Processing Line refers to a set of machinery and equipment designed for the production and processing of quail eggs in a brine solution. The brine is a solution of water, salt, and sometimes other additives, used for preserving and enhancing the flavor of the eggs. This processing line typically involves several stages to clean, sort, preserve, and package quail eggs in a brine solution.

Pre-cooking machine – egg boiling machine – pre-cooling – cooling tank – shell crusher – lifting after crushing – egg separation and conveying – shelling – white egg conveying – egg shell conveying – collecting white eggs

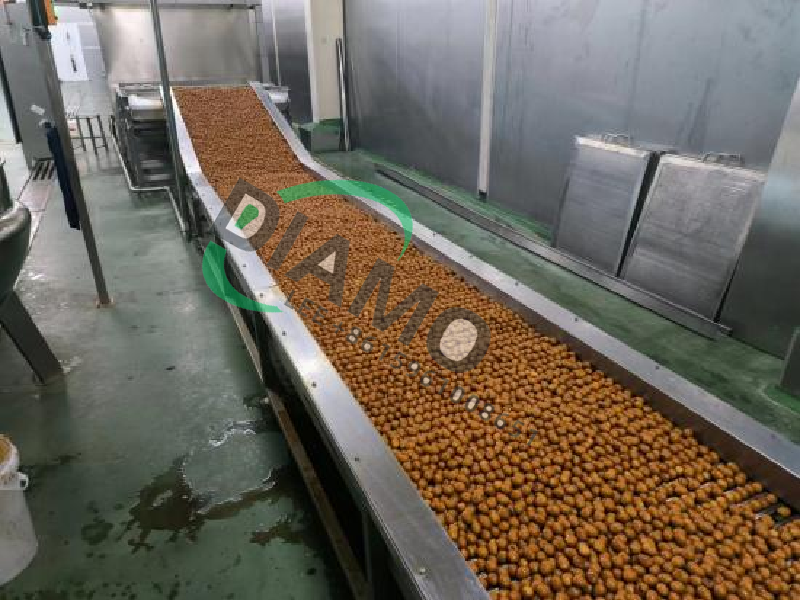

Cooling conveyor line after braised – hot air dryer conveyor – cooling and air-drying selection of braised eggs

Boiling quail eggs typically requires a shorter cooking time compared to chicken eggs due to their smaller size. For soft-boiled quail eggs with a runny yolk, you can boil them for about 2 to 3 minutes after the water reaches a rolling boil. If you prefer hard-boiled quail eggs with a fully cooked yolk, you can let them boil for around 4 to 5 minutes.

Keep in mind that the exact timing may vary based on factors such as the size of the eggs, altitude, and the initial temperature of the eggs (whether they are at room temperature or cold from the refrigerator). It’s a good idea to experiment a bit to find the perfect boiling time that suits your preference. After boiling, immediately transfer the quail eggs to an ice bath to stop the cooking process and make them easier to peel.

1. It is advisable to use quail eggs placed for 3-5 days in Summer . Around 7days in Winter .

2. Soak the quail eggs in cold water for 5-10 minutes before boiling the eggs

3. When the water is 70 degrees, gently pour the quail eggs into the cooking machine and stir slowly to make the egg yolk-centering , After the water is boiled, Don’t scoop out the egg, continue to cook for 10 minutes

Quail Egg cooking Machine

The high-temperature cooking equipment employs a proprietary technology to ensure the uniform heating of quail eggs, emphasizing precise egg yolk centering in preparation for high-temperature boiling. Incorporating a steam-boiled egg spiral transmission system, this innovative approach allows quail eggs to be expertly flipped during the cooking process. The centralization of quail eggs within the cooking area ensures an even distribution of heat, facilitating rapid and thorough cooking. Through this method, each quail egg is subjected to consistent heating, guaranteeing quick and efficient cooking. This meticulous process not only exemplifies technological sophistication but also underscores a commitment to delivering perfectly cooked quail eggs with a harmonious blend of convenience and culinary precision.

Quail Eggs Shell Breaking

The quail egg shell-breaking process plays a pivotal role in facilitating the subsequent peeling step, ensuring a smoother and more efficient operation. This technique is seamlessly integrated with a specialized quail egg peeler, designed to break the shell uniformly. This meticulous approach not only enhances overall efficiency but also significantly reduces the rate of damage to the delicate quail eggs. By breaking the shells evenly, the process minimizes the risk of wastage while streamlining the subsequent peeling stage. The strategic synergy between the shell-breaker and peeler underscores a commitment to precision and operational excellence, ultimately contributing to the production of high-quality quail eggs.

Quail Eggs Peeling

In the meticulous process of peeling fractured quail eggs, a sophisticated egg collection conveyor belt efficiently sieves out any subpar egg products. The peeling procedure boasts an impressive success rate surpassing 98%, ensuring that the final quail eggs exhibit a remarkable smoothness and aesthetic appeal. This intricate system not only guarantees the elimination of defective eggs but also contributes to the production of visually pleasing, high-quality quail eggs. The commitment to precision in each step of the peeling process underscores the dedication to delivering a superior product, culminating in a batch of quail eggs that not only meet stringent standards but also captivate with their flawless appearance.

Taixing Aerospace Machinery Technology Co., Ltd