Dirección:China

Horario de trabajo :de lunes a viernes: de 7.00 a 19.00 horas

Fines de semana De 10.00 a 17.00 horas

Dirección:China

Horario de trabajo :de lunes a viernes: de 7.00 a 19.00 horas

Fines de semana De 10.00 a 17.00 horas

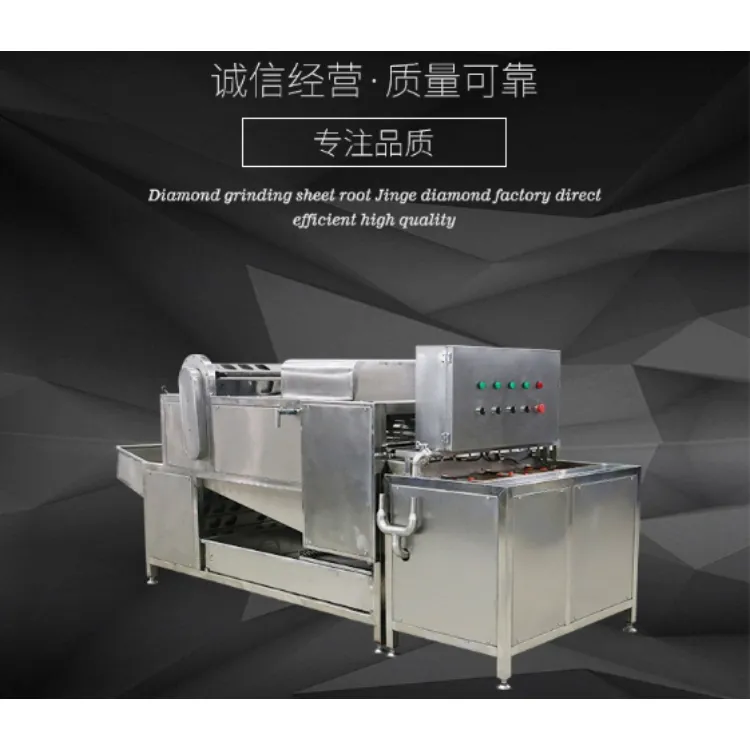

En hen egg peeler machine represents a remarkable innovation in the realm of food processing equipment, specifically designed to streamline the peeling of hard-boiled chicken eggs. Its versatility makes it an ideal choice for a range of settings, including small processing plants, central kitchens, and restaurants, revolutionizing the egg peeling process.

En hen egg peeler machine represents a remarkable innovation in the realm of food processing equipment, specifically designed to streamline the peeling of hard-boiled chicken eggs. Its versatility makes it an ideal choice for a range of settings, including small processing plants, central kitchens, and restaurants, revolutionizing the egg peeling process.

| Modelo | Capacidad | Depósito de agua Dimensión

(mm) |

Peeling machine Dimension (mm) | Potencia |

| HT-1500 | 1500eggs/h | 1800*800*400 | 1200*850*950 | 1kw |

| HT-5000 | 5000eggs/h | 2454*966*1373 | 2200*1700*1800 | 2,07 kW |

| HT-8000 | 8000eggs/h | 2454*966*1373 | 2200*1700*1800 | 3.14kw |

| HT-10000 | 1000eggs/h | 2454*966*1373 | 2800*1700*1800 | 4kW |

One of its standout features is the efficiency it brings compared to manual egg peeling methods. While manual peeling can be time-consuming and labor-intensive, this machine simplifies the entire process. With its peel rollers and strong water impact, the machine adeptly removes eggshells without damaging the delicate egg surface. This ensures that the final product boasts a smooth and aesthetically pleasing appearance, a crucial aspect for industries where visual appeal matters.

Moreover, the machine’s design is not just about efficiency but also about resource conservation. Its cycle water tank mechanism enables substantial water savings, a critical factor in today’s environmentally conscious world. By recycling water within the system, it minimizes wastage, making it an eco-friendly choice for egg processing.

Ease of operation and cleaning further enhance its appeal. The machine’s user-friendly interface and straightforward operation make it accessible for operators of varying skill levels. Its design prioritizes simplicity, allowing for easy maintenance and cleaning procedures, thus saving both time and labor.

Furthermore, the incorporation of rubber rollers and the utilization of strong water impact contribute to a significant reduction in egg breakage rates. This ensures that a higher percentage of eggs remain intact during the peeling process, reducing waste and maximizing yield—a crucial advantage for businesses aiming to optimize their production output.

Space efficiency is another notable characteristic. Despite its advanced capabilities, the machine boasts a compact design that doesn’t occupy excessive floor space. This makes it a practical addition even to settings where space is a premium, ensuring that the operation remains efficient without compromising on available workspace.

the hen egg peeler machine stands as a testament to technological advancements in food processing equipment. Its blend of efficiency, conservation, ease of use, and space-saving design makes it a valuable asset for various industries reliant on the seamless peeling of hard-boiled chicken eggs.

An industrial egg peeling machine significantly boosts efficiency in food production. For instance, in a commercial setting where a large quantity of hard-boiled eggs is needed, manually peeling eggs can be time-consuming and labor-intensive. With an egg peeling machine capable of handling hundreds or thousands of eggs per hour, the production rate increases significantly. This improvement in efficiency reduces labor costs and increases overall output, streamlining operations in food processing plants, catering services, or large-scale kitchens.

Egg peeling machines ensure a consistent and high-quality output. Manual egg peeling often leads to variations in the peeling process, resulting in some eggs being better peeled than others. This inconsistency can affect the visual appeal and overall quality of the final product. However, using an automated egg peeling machine with a no-scratch peeling technique ensures uniformity in the peeling process. The machine operates with precision, removing shells without damaging the eggs, resulting in a consistent, high-quality product suitable for packaging, retail, or further food processing.

Investing in an egg peeling machine can lead to cost savings and reduced wastage. When eggs are peeled manually, there’s a higher likelihood of egg breakage or damage during the peeling process. This leads to waste and increased costs due to discarded or unusable eggs. In contrast, an efficient egg peeling machine, especially one with a high yield rate and low breakage percentage like the one described, minimizes egg damage during peeling, thus reducing waste and maximizing the number of usable eggs. This reduction in wastage translates to cost savings for businesses in terms of raw material usage and increased product yield.

These examples highlight how an egg peeling machine positively impacts efficiency, quality consistency, and cost-effectiveness in various food production settings, contributing to smoother operations, improved product quality, and reduced waste.