Address:China

Working time :Monday to Friday: 7am to 7pm

Weekends: 10am to 5pm

Address:China

Working time :Monday to Friday: 7am to 7pm

Weekends: 10am to 5pm

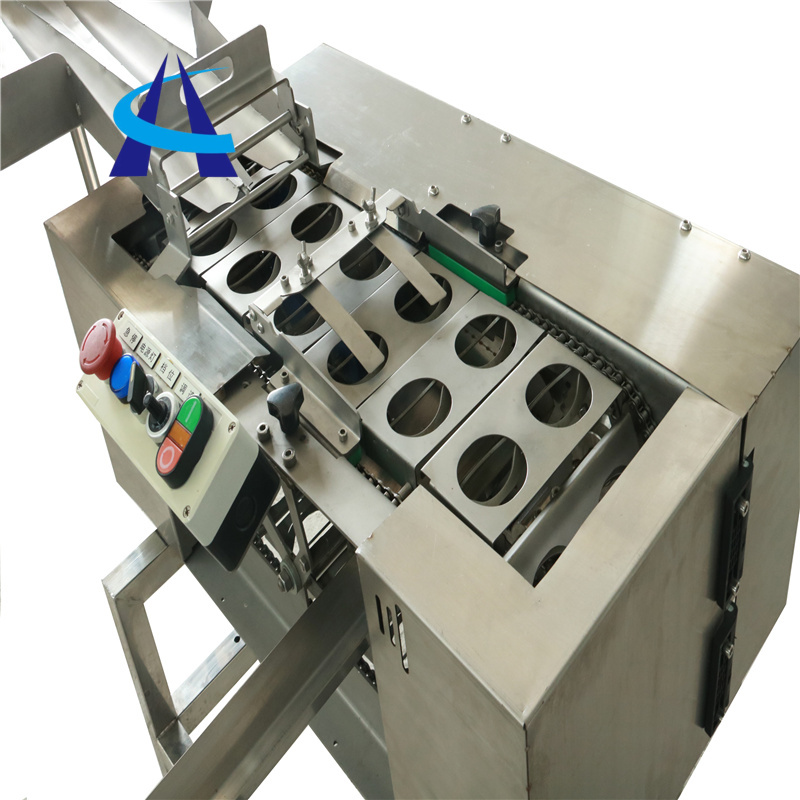

With the continuous advancement of science and technology, automation equipment plays an increasingly important role in various fields. Among them, the fully automatic egg breaker machine, as a new processing equipment, is gradually entering the food processing and catering industries. The automated egg breaker machine not only improves work efficiency, but also ensures the hygiene and quality of food processing. However, you may encounter some problems during long-term use. Next, we will introduce to you the common faults and solutions of egg breaker .

1. There is a power problem or the egg breaker does not respond.

An unstable power connection or damaged power cord may prevent the egg breaker machine from starting. Check whether the power socket and power cord are securely connected and make sure the power supply is normal. If the power cord is found to be damaged, replace it with a new one.

If the egg breaker machine does not respond when the start button is pressed, there may be a problem with the control system. Check whether the control panel, switches and circuit connections are normal. If there is damage or looseness, repair or replace relevant parts in time.

If the egg shell is not completely broken, it may be caused by not breaking it hard enough. According to the adjustment method of the equipment, gradually increase the knocking intensity to ensure that the eggs can be fully cracked. Knocking too hard may cause the egg liquid to spill out, affecting the quality of the food. It is necessary to gradually adjust the breaking strength to avoid excessive damage to the eggs.

Fragments of egg shells may get stuck in the breaking parts, causing the equipment to become stuck and unable to operate properly. Before use, be sure to clean the equipment of any residue and ensure that the striking parts are unobstructed.

Long-term use may cause dust or grease to accumulate in mechanical parts, resulting in poor machine operation. Clean and lubricate equipment regularly to ensure proper functioning of mechanical components.

Long-term use will cause wear and tear of some parts, such as motors, switches, etc. Check each component regularly. If wear or aging is found, replace it in time to maintain the normal operation of the equipment.

Some devices are configured with a fault display function. When a fault occurs, the device will display the corresponding error code. According to the displayed code, search the device manual and find the corresponding troubleshooting method.

The common faults and treatment methods of egg breaker machine have been introduced to you. In daily operations, operators also need to be familiar with the use of the equipment and precautions to reduce the occurrence of faults. If you encounter a fault that cannot be solved, you should contact qualified maintenance personnel in time to ensure that the equipment can operate normally and produce the expected results. At the same time, regular maintenance and upkeep are also important steps to ensure the normal operation of the equipment.