Address:China

Working time :Monday to Friday: 7am to 7pm

Weekends: 10am to 5pm

Address:China

Working time :Monday to Friday: 7am to 7pm

Weekends: 10am to 5pm

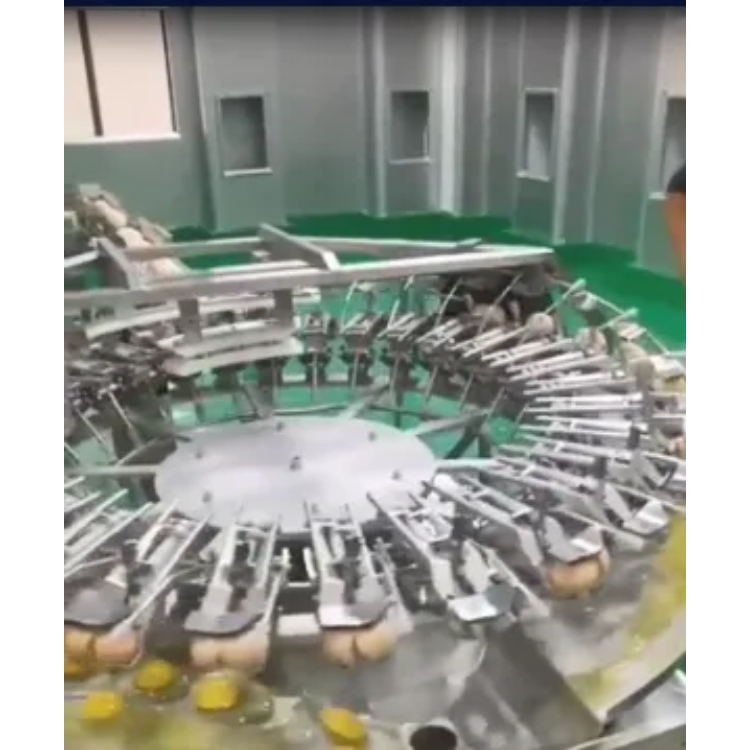

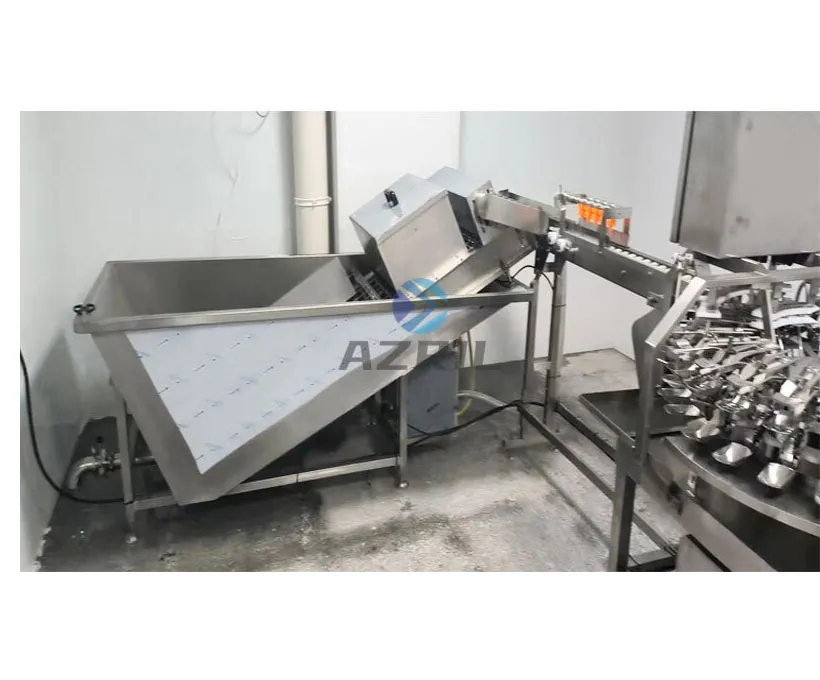

Egg Breaking And Separator Machine is a common equipment in food factories, used to automatically break and crack egg shells to improve production efficiency and product quality. Below Diamo Lee will introduce the advantages of using Egg Breaking And Separator Machine in food factories and some precautions.

1. Improve production efficiency and ensure product quality

The egg breaking separating machine can automatically complete the work of breaking and cracking egg shells, which is faster and more energy-efficient than manual operation. It can operate accurately and continuously, greatly improving production efficiency and saving labor costs.

The egg breaking separating machine can accurately crack eggshells, avoid mixing of egg yolk and egg white, and ensure product quality and hygienic safety. Through standardized operations, each eggshell is struck evenly to prevent eggshell residue or fragments from entering the product.

Reduce Manual Labor Intensity

The traditional eggshell cracking and breaking process requires a large amount of manpower investment, which can easily lead to operator fatigue and work-related injuries. The egg cracking machine can automatically complete these tasks, reducing the labor intensity of the operator and improving the comfort of the working environment.

Egg cracking machines usually have multiple modes and adjustment functions that can adapt to different specifications and types of eggs. The shell breaking strength and the number of knocks can be adjusted as needed to adapt to different product requirements.

Some higher-end industrial egg breaking machine are equipped with data recording functions that can record the cracking of each egg shell and the results of the breaking . This is beneficial for quality traceability and production management, helping to monitor and improve the production process.

Operators should follow operating procedures and safety requirements when using the egg cracker, and properly wear personal protective equipment, such as gloves and goggles. Keep hands or other body parts away from operating equipment to prevent injuries.

Regularly inspect and maintain the industrial egg breaking machine to ensure the normal operation and safety of the equipment. Keep the equipment clean, replace worn parts in a timely manner, and perform lubrication and adjustments to extend the service life of the equipment.

Egg crackers can usually adapt to eggs of different specifications and sizes, but they must be adjusted according to the actual situation during use. Make sure the eggshells are cracked evenly to avoid damaging the yolk or white due to excessive breaking .

Regularly check the breaking effect of the egg cracker regularly to ensure that each eggshell can be fully cracked without any residue or fragments. If the breaking effect is found to be unsatisfactory, adjust the equipment or replace parts in time to ensure product quality.

To sum up, the use of egg breaking machines in food factories has the advantages of improving production efficiency, ensuring product quality, and reducing manual labor intensity. However, when using an egg cracker, you need to pay attention to safe operation, regular maintenance, adapting to eggs of different specifications, and monitoring the egg cracking effect. Only by using the egg cracking machine rationally and maintaining it correctly can we give full play to its advantages, improve production efficiency and product quality, and contribute to the development of food factories.